Services - Pièces de rechange

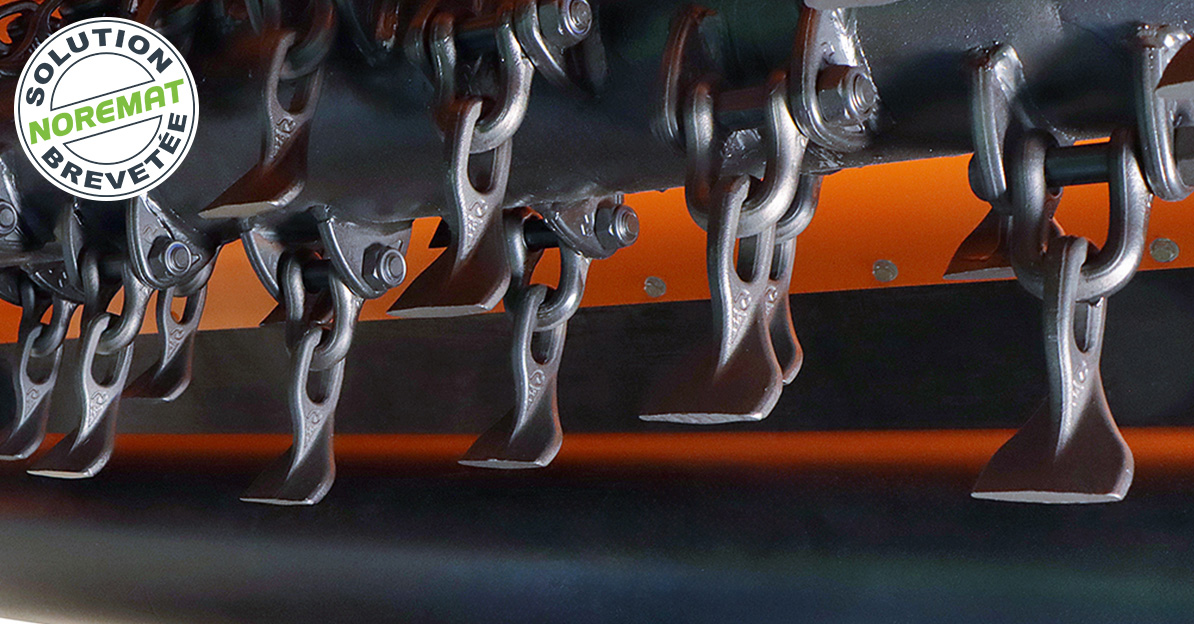

FORSACTIV flails New

The FORSACTIV System

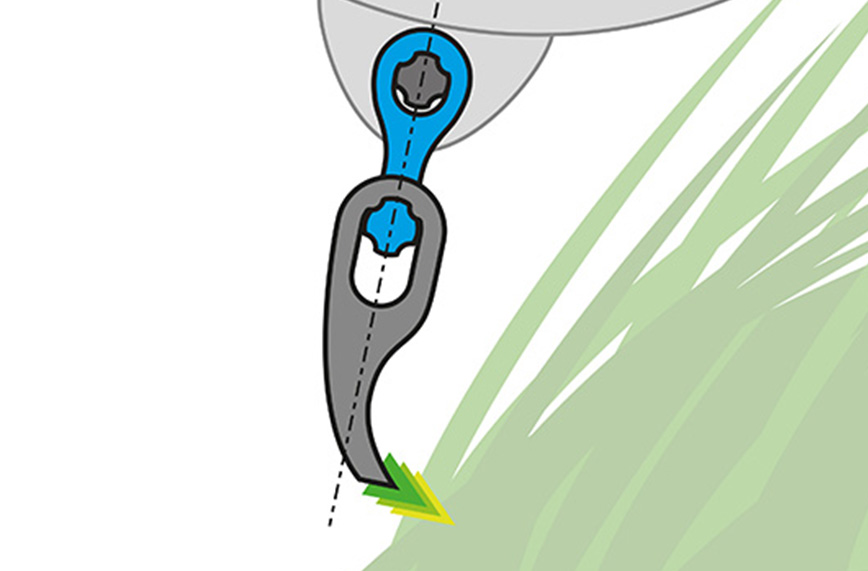

- Low-energy knives are based on the principle of centrifugal support and kinematic chain rigidity. The special bore of the flail, shackle and yokes ensures that all parts are held on the same axis.

- This design makes it possible to reduce rotor speed by 10% without any loss of efficiency or output. The reduction in rotor speed is achieved by reducing the speed of the carrier's combustion engine. Depending on site configurations and carriers, fuel savings average 10% to 15%.

- Resistance to impact and wear thanks to careful choice of materials, giving Forsactiv knives longer life.

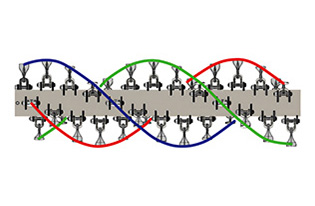

- Wider than conventional spoons, the number and arrangement of Forsactiv knives on the rotors facilitate material evacuation.

- Combining reduced energy consumption with reduced material consumption, Forsactiv is part of an eco-responsible approach.